CNC Sharpening Services

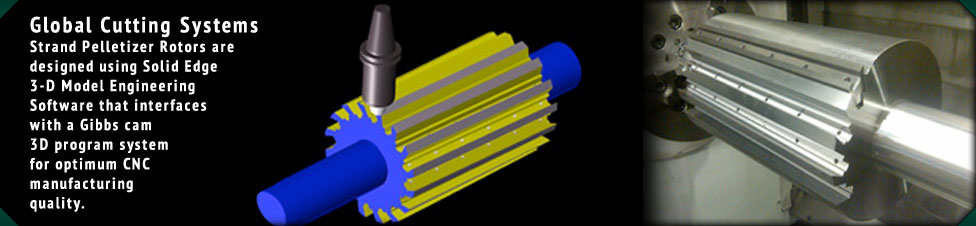

Strand Pelletizer Rotors

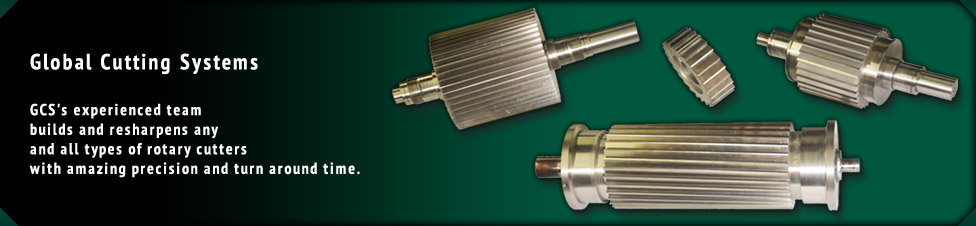

GCS offers a CNC Sharpening and Repair program for all styles of original equipment manufacturers of pelletizer rotors.

Rotor Inspection

CNC Grinding

CNC Dual Grinding

- Incoming GCS 8-step visual Inspection Evaluation on all rotors within 24 hours of delivery

- Rotors are serialized with a GCS identification number for Rotor Life Tracking

- Review of OEM minimum size requirements and customer preferred speciations

- ICR-Inspection cost reports are e-mailed to our customer for immediate evaluation for the customer purchase order approval

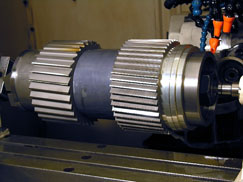

- Pelletizer rotors are ground on 5 axis continuous pass CNC grinders to insure the correct OEM flute geometry profiles tooth to tooth for consistent pellet quality

- TSP-Triple Sharpening Process provides grinding the flute depth, primary and secondary angles

- In House Weld Repair for rotor’s, bearing journals, carbide and ceramic coatings

- QCR Quality Control Reports are provided after final inspection

- Rotors are tagged, secured, and shipped by customer preferred freight carrier

- Rotor replacement Life Tracking analysis reports provide for year end budget approval

- 24 hour emergency service is available

- GCS offers services on rotors ranging from 25mm to 1000mm in length, 20 inch diameter

Exact Flute to Flute Geometry

Protective Coating

GCS Rotor Shipping Box

GCS Sharpens the following Rotor Models and Styles

Automatik USG-ASG Series Rotors

Automatik USG-ASG Series Rotors

Cumberland Quietizer Rotors

Cumberland Quietizer Rotors

Cumberland Bolt On Series Rotors

Cumberland Bolt On Series Rotors

Conair 200 Series Stellite

Conair 200 Series Stellite

Conair 200 Series PF Wedge Lock Rotors

Conair 200 Series PF Wedge Lock Rotors

Conair 3000-3500 Series Wedge Lock Rotors

Conair 3000-3500 Series Wedge Lock Rotors

Conair 300 Series Pelletizer Rotor

Conair 300 Series Pelletizer Rotor

Carbide Inlay Pelletizer Rotors

Carbide Inlay Pelletizer Rotors

Scheer Pelletizer Rotors

Scheer Pelletizer Rotors

New Stellite Rotors

New Stellite Rotors

Pultrusion Pelletizer Rotor

Pultrusion Pelletizer Rotor

Pelletizer Rotor Secured Shipping Box

Pelletizer Rotor Secured Shipping Box