About Global Cutting Systems

The Global Cutting Systems company offers 31 years of industrial manufacturing servicing the Pulverizer, Roto-Molding, Plastics Compounding and Recycling Industries.

The Global Cutting System/King Machine Group began manufacturing OEM Pulverizer blades and providing CNC sharpening services in 1980. In 1994 King Machine expanded into the manufacturing of Pulverizer machinery for Reduction Engineering ending production in 2001. In 2003 the King machinery group then became the OEM Supplier for the Powder King Pulverizer company ending production in 2008. GCS continues to supply blades and spare parts for all OEM Pulverizer machinery.

In 2010, King formed Global Cutting Systems, LLC to manufacture Global Cutting Systems Pulverizer machinery, Strand Pelletizer spare parts and Underwater and Hot Face Pelletizer Melt Plate Dies.

Global Cutting Systems offers a state of the art 22,000 square foot machining facility located In Massillon, Ohio. GCS is supported by a team of engineers and journeyman machinists that bring years of Pulverizer and Pelletizer manufacturing expertise.

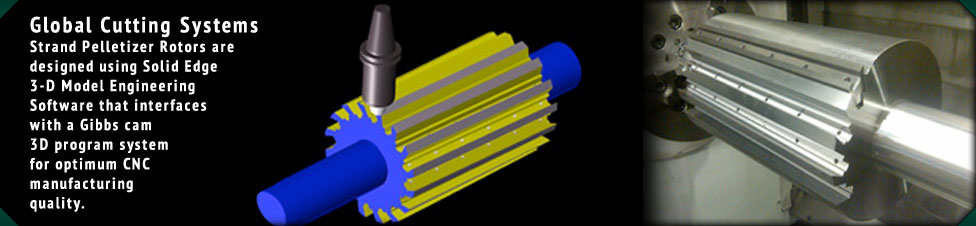

GCS houses state of the art CNC manufacturing and CNC grinding equipment. Our professional engineering staff is supported with Solid Edge 3D solid model engineering software and GibbsCAM 3D programming system. This investment will allow GCS to become an industry leader in Design and Technology for OEM Equipment, CNC Sharpening, Auxiliary Parts and Technical Support Services.

Global Cutting Systems manufactures 5 model’s of Pulverizer machinery. The 200 Lab Mill offers lab quality with small batch pulverizing processing. The GCS1500 is designed to fit the demands of the moderate processor while the GCS1500XP Unit is expandable into a Model GCS2500 Dual Mill operation. The GCS2500DF is a dual feed unit and works as Dual Primary Mill is designed for continuous production for 10 - 80 mesh materials.

All Machines are designed with unique features only offered with the GCS Pulverizer Systems.

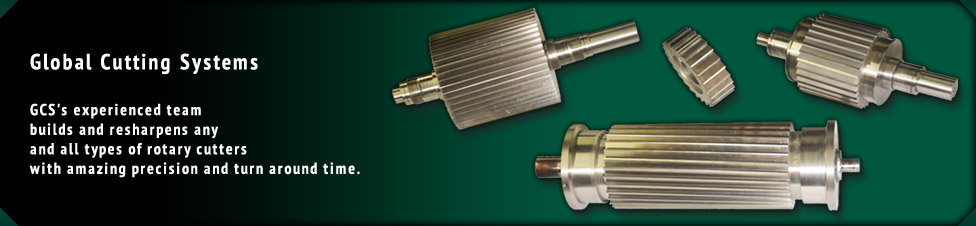

The Global Cutting Systems Sharpening Service Program begins with our Customer Pre-Certification Inspection Process (CPIP) on incoming Rotors, Blades and Dieface plates for repair and sharpening. After receiving a confirmation of the customer approval, all work is then performed and completed with the GCS 8 point quality control inspection process and final certification.

The Staff at GCS is truly committed in providing our customers with “On Time Customer Service”. This philosophy guarantees immediate answers to your Pulverizer and Knife requirements. Global Cutting Systems wants the opportunity to earn your business.

To inquire about your GCS Pulverizer OEM Machine or CNC Sharpening Blade Requirements please call at 330-833-2111.

GCS/King Machine & Tool Co. Timeline

1994- Manufactured the first private labeled pulverizer machine for an OEM in Ohio

1995- First to introduce Creep Feed Grinding Technology

1996- First to include PLC-driven control panels to automate the pulverizing process

2002- First to control airflow through the mill housing

2002- First to incorporate single push-pull adjustment for gapping the blade

2002- First to incorporate hold down rings to secure the grinding disc

2003- Manufactured the first private labeled pulverizer machine for an OEM in Arizona

2003- First to build a miniature pulverizer for laboratory applications (Lab Mill)

2004- First to introduce direct-drive technology in the pulverizing process

2006- First to patent the pulverizing mill assembly

2009- First to successfully grind PET materials for recycling

2010- Global Cutting Systems created to manufacture new Pulverizer Systems